What about the lead time of desktop cnc lathe from placing a order to delivery?

2020-11-06

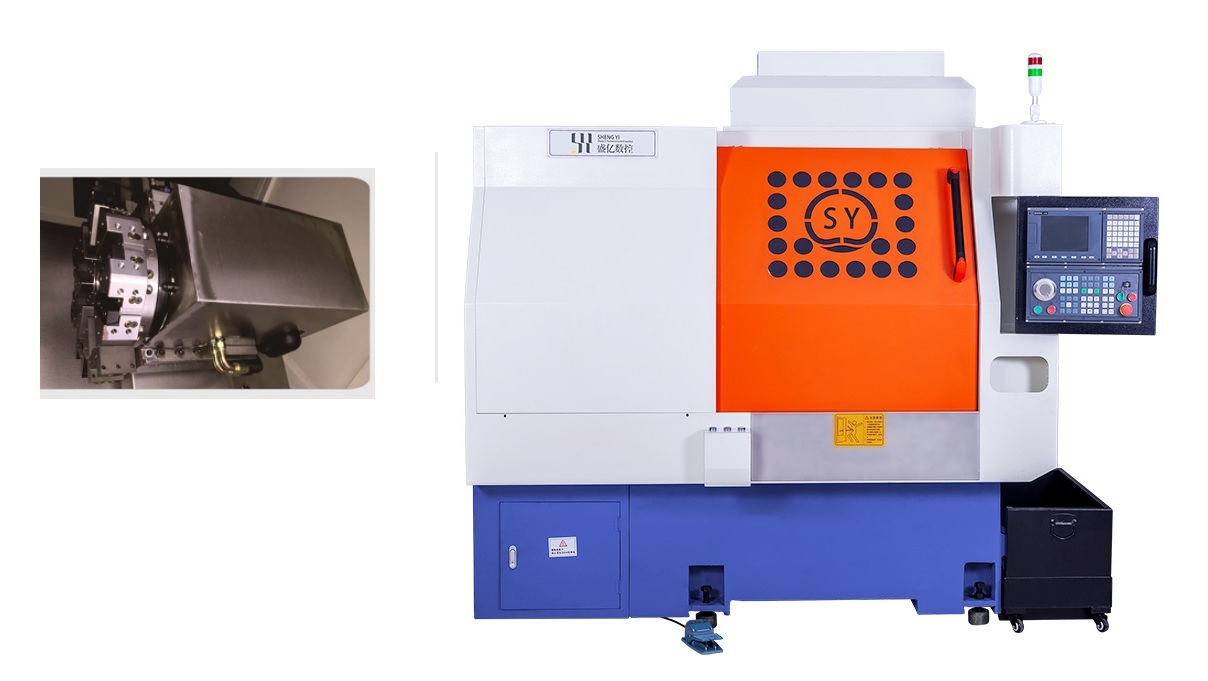

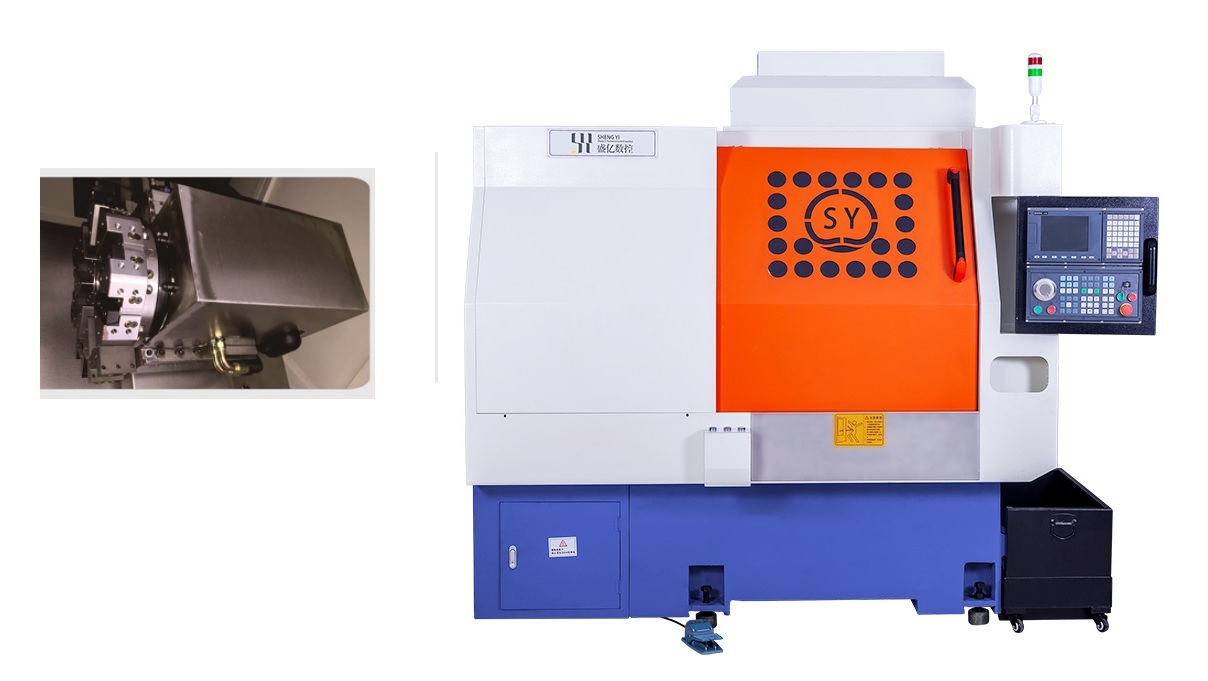

Our lead times vary depending on material availability and production queue. We have several options to expedite the process if the project calls for it. An GUANGDONG Sunny CNC Machinery Co.,Ltd. representative can give you an accurate estimate based on the specifics of your project. Lead time is an extremely important factor when choosing a supplier for manufacturing desktop cnc lathe. Sunny CNC Machinery does a good job in lead time. The pursuit of lead time adds our customer's satisfaction.

The popularity of the Sunny CNC Machinery brand shows strong technical strength. The cnc machine parts series has many styles to meet the diversified needs of customers. Sunny CNC Machinery cnc machine parts is inclusively tested by third-party testing organizations. It is tested in terms of abrasion, adhesion, colorfastness, dimensional stability, hardness, thickness, and tear strength. Its appearance is anti-aging and maintains a brand new status. This product significantly contributes to alleviating people's foot pain, improving feet performances and maximizing comfort from heel to toe. It is free of changing mould or clamp when it processes different parts.

We’re working hard to embed sustainability across the business. We focus on reducing our negative impacts on the environment whilst maximizing economic and social value.

The popularity of the Sunny CNC Machinery brand shows strong technical strength. The cnc machine parts series has many styles to meet the diversified needs of customers. Sunny CNC Machinery cnc machine parts is inclusively tested by third-party testing organizations. It is tested in terms of abrasion, adhesion, colorfastness, dimensional stability, hardness, thickness, and tear strength. Its appearance is anti-aging and maintains a brand new status. This product significantly contributes to alleviating people's foot pain, improving feet performances and maximizing comfort from heel to toe. It is free of changing mould or clamp when it processes different parts.

We’re working hard to embed sustainability across the business. We focus on reducing our negative impacts on the environment whilst maximizing economic and social value.