Will Sunny CNC Machinery become an OBM in future?

2020-10-28

Becoming an OBM is a daunting task and long-term goal for GUANGDONG Sunny CNC Machinery Co.,Ltd.. It not only requires the enterprises' own efforts in developing their own production capacity and innovation capacity but also needs the support of local government policies and further the Government if possible. The transformation from an ODM or OEM service provider to an OBM provider implies the company has turned into an innovation-based company from a manufacturing enterprise. With this goal deeply rooted in our mind, it drives us to concentrate more on improving our R&D strength and developing our core technology. Only in this way can we gain an increasing level of operation and management, thereby moving toward higher levels of capital operations and becoming a competitive OBM.

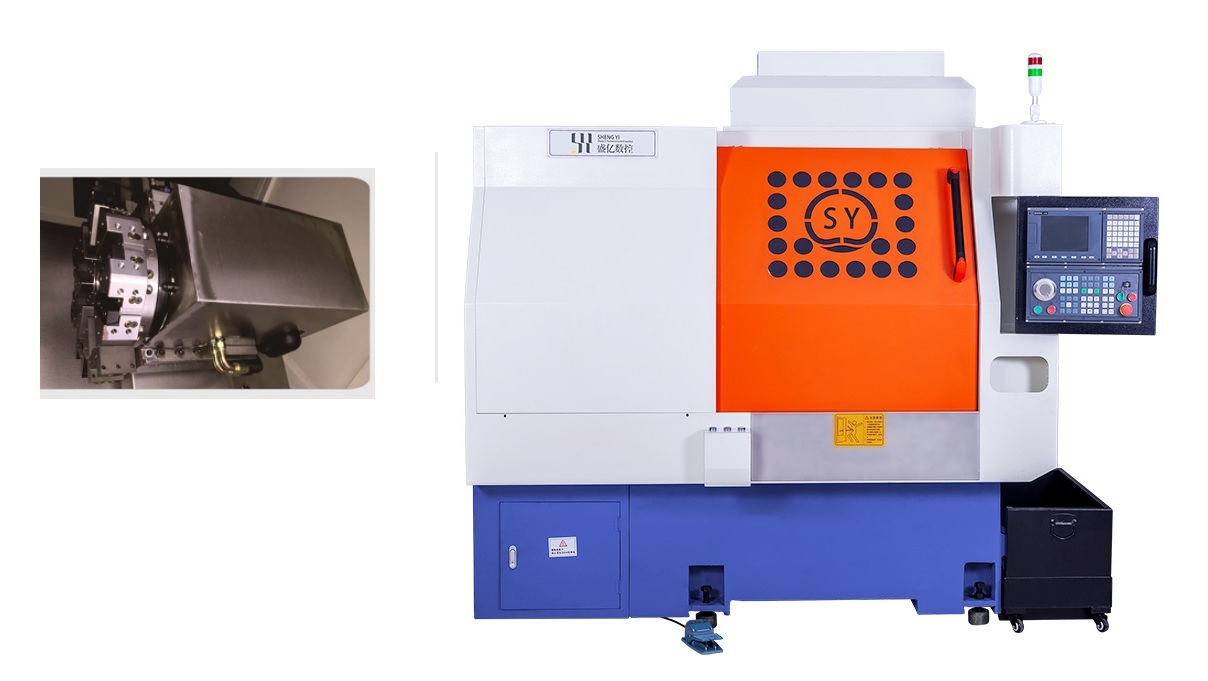

Sunny CNC Machinery is widely known as one of the pioneers in manufacturing lathe machine accessories. We offer quality products in this field for many years. Sunny CNC Machinery provides a wide range of cnc lathe for customers. Sunny CNC Machinery cnc machine parts undergoes a series of production methods such as sanding, painting, and ovendry. All these methods are strictly carried out by our professional workers. Its fast tool changing can greatly shorten the processing time. CRI is not the only way to judge the 'quality' of light. The product also performs well with consistent light output. A lot of measuring methods are developed to ensure the color output of the product. Its lubrication system can automatically shut down to avoid waste of lubricating oil.

our team will stick to using the first-class technology, first-class management, first-class products and first-class service to return customer. Ask!

Sunny CNC Machinery is widely known as one of the pioneers in manufacturing lathe machine accessories. We offer quality products in this field for many years. Sunny CNC Machinery provides a wide range of cnc lathe for customers. Sunny CNC Machinery cnc machine parts undergoes a series of production methods such as sanding, painting, and ovendry. All these methods are strictly carried out by our professional workers. Its fast tool changing can greatly shorten the processing time. CRI is not the only way to judge the 'quality' of light. The product also performs well with consistent light output. A lot of measuring methods are developed to ensure the color output of the product. Its lubrication system can automatically shut down to avoid waste of lubricating oil.

our team will stick to using the first-class technology, first-class management, first-class products and first-class service to return customer. Ask!